Building Structural

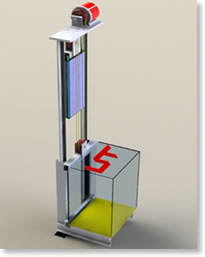

Hoistway

Also known as the shaft. The space designated for the support and travel of an elevator. It is characterized by three main dimensions: Overhead Clearance, Pit, and Travel.

Overhead Clearance

Distance measurement from top-most floor landing to top of hoistway (normally characterized by building rafters over hoistway).

Pit

Section of Hoistway below the bottom-most floor landing. Pit-depth is distance measurement from bottom-most floor landing to poured concrete pad at bottom of hoistway. The Pit is required to make room for the sling assembly when the car is sitting at the bottom-most floor.

Travel

Distance measurement from bottom-most floor landing to top-most floor landing.

Car

Cab/Car

Enclosure that passengers ride in. We offer standard, signature, and executive cab designs as well as custom made designs to suit your needs.

Car Station

Operating panel in the car that contains elevator buttons, and other features such as key switches.

Control Systems

Controller

Electrical control circuitry for elevator self-contained in an electrical controller box that is located externally to hoistway in both MRL and Hydraulic elevators. In Hydraulic, it is normally attached to the pump unit.

Control Valve Unit

Hydraulic Valve control unit used to control motion in Hydraulic Elevators. Through a series of valves, hydraulic fluid flow is controlled to produce smooth acceleration and deceleration.

VVVF

Variable Voltage Variable Frequency control used in MRL Elevators. By using VVVF to actively adjust the frequency and voltage amplitude of the supply mains going to the AC machine, the torque-speed characteristic can be precisely controlled. This produces smooth acceleration and deceleration.

Door Systems

Car Door

The door attached to the elevator car which directly accesses the cab interior. The car door moves along with the elevator.

Car Gate

Alternative to car door in the form of an accordion gate or bi-folding gate.

Door Interlock

Electromechanical door lock assembly located at each hall door. The lock is wired to the central elevator controller that monitors the door state as opened or closed. This ensures the elevator will only run if all doors are closed, and that the door cannot open unless the elevator is stopped at that floor.

Hall Door

The stationary door attached to the hoistway which accesses the car door when the elevator arrives at a floor level. It remains locked when the car is not at floor level.

Sliding Door System

Automated elevator door system coupling a sliding metal car door to a sliding metal hoistway door so that they both open and close together.

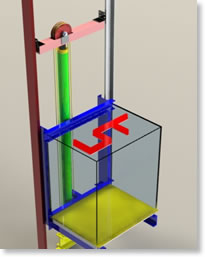

Drive Systems

Hydraulic Jack

Assembly consisting of a cylinder and sealed piston rod. Fluid pressure within the cylinder moves the piston rod moves upward or downward driving the elevator.

MRL

Machine Room-less drive system for complete in-shaft elevators. It consists of a permanent magnet AC synchronous machine and counterweight assembly.

Pump Unit

Metal tank enclosure housing hydraulic oil, submersible pump and motor used to run a hydraulic elevator.

Elevator Structural

Guide Shoes

C-shaped attachments on the sling that fit snugly over the rails to guide the sling (and car) up and down. They have rubber padding to reduce friction and noise between stationary rail and moving sling.

Platform

Structural base of car that sits on top of the sling channels.

Rails

T-shaped steel tracks that run the entire length of the hoistway for which the elevator runs. They are plumb (aligned perfectly vertical) and act as a guide for the car to move upwards and downwards.

Rail Brackets

Welded Structural Steel Brackets that tie the rails to the load bearing wall of the hoistway.

Sling

The supporting frame for which the car sits on. It is designed to structurally take the car static and occupancy loads and moves up and down along the rails.

Floor Features

Call buttons

Buttons exterior to the shaft which call the elevator to the current floor.

Hall Station

The operating panel housing elevator call buttons and user interface components such as indicator lights and arrows.

Hall Lantern Unit

Position indicator of the most current car position. It is digitally displayed.

Landing

Refers to floor stop. The terminal landings refer to the top-most and bottom-most floors. There is extra safety features to ensure the elevator does not go beyond terminal landings.

Operation

Automatic Operation

Hall station and Car station buttons only need be pressed momentarily to place a call with the elevator. The Car station has one marked floor button per landing served and the Hall station has one button to call the elevator to that floor.

Constant Pressure Operation

Car station and hall station buttons must be constantly pressed to operate the elevator. Once elevator reaches landing levelling zone, visual indicator notifies passenger that it is ok to release button pressure. The automatic levelling function will then ensure the car is perfectly level with the floor landing.

Levelling Zone

Small vertical distance about each landing that is marked by proximity or limit switches in the hoistway. When the car passes within this zone, a cam actuates these switches signalling that car is in levelling zone. Used in conjunction with elevator’s Auto-Levelling feature.

Safety Codes

ASME 17.1

American Society of Mechanical Engineers Safety Code for Elevators. Section 5.3 outlines Private Residential Elevators.

CSA B44

Canadian Standards Association Safety Code for Elevators

Safety Components

Auto-Levelling

Elevators automated ability to level itself as long as it is within the levelling zone. This only applies to Constant Pressure operation where operator may release button pressure at some point within levelling zone. Automatic operation is already calibrated to stop at each floor landing precisely. It uses a control system to ensure car stops safely at floor level.

Battery Backup

Battery backup converts DC to AC and supplies machine with enough juice to run elevator and elevator lights in case of power outage.

Manual Lowering Valve

A hydraulic elevator safety. A valve located on the control valve unit that can be manually opened to allow fluid to flow back into the pump unit lowering the car to the desired level. In case of power outage, this can be used to safely lower the elevator to a floor level.

Speed Governor

An MRL Elevator safety device. Governor consists of pulleys that spin freely with motion of elevator. If overspeed occurs, centrifugal force activates a sensor in the governor that cuts electrical power to the machine. In the case of down overspeed, there is an added mechanical safety. The governor wheel will catch onto a mechanical stop stopping it from spinning. This stop will cause a brake linkage to wedge onto the rails halting the elevators motion.

Terminal Limit Switches

Cuts power to machine and stops elevator if motion over-runs normal floor stop at terminal landings