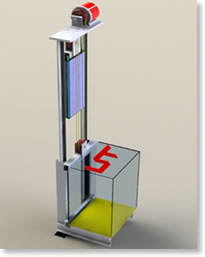

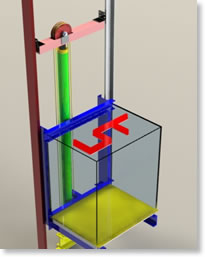

The interaction between glass and light provides a unique opportunity for heightened architectural design. In essence, when glass is used, he visual impact of the hoistway, the structural portion of the elevator, and the lighting design may now be considered in addition to the cab design. When using glass, it is as important to design for when the car/cab is not in a location as it is for when it is.

As the industry leader in glass elevators, we create designs that accentuate the inherent properties of light. We encourage windows and skylights to bring natural light into the hoistway and home. Glass as a material offers a modern elegance when applied to home elevators.

UT Elevator is at the forefront of glass elevator technology and glass as a material offers a modern elegance when applied to home elevators. With our technical ability and artistic touch, we are the premier choice when it comes to glass.